Understanding Optimal Pressure Levels for Efficient Heating Systems

Boilers are central heating systems that provide warmth and comfort to residential and commercial buildings. They play an all-important role in maintaining a comfortable indoor environment during colder months. In this comprehensive guide, we will explore boilers in detail, covering their types, components, working principles, maintenance, and benefits. Whether you’re a homeowner, renter, or simply interested in learning about heating systems, this article will provide valuable insights into the world of boilers.

1. Types of Boilers:

a. Combi Boilers: Combination or combi boilers serve both heating and hot water needs in one lone unit. They are popular for their space-saving design and efficiency.

b. System Boilers: System boilers work with a separate hot water cylinder and provide heating to radiators or underfloor systems. They offer high water pressure and are suitable for more sizeable properties.

c. Conventional Boilers: Also known as regular or traditional boilers, conventional boilers consist of a boiler unit, hot water cylinder, and cold water storage tank. They are suitable for properties with high hot water demands.

2. Components of a Boiler:

a. Boiler Unit: The main component that heats water or generates steam for heating purposes.

b. Heat Exchanger: Transfers heat from the burner to the water or steam.

c. Burner: This device ignites and combusts fuel (such as natural gas, oil, or biomass) to produce heat.

d. Pump: Circulates water or steam throughout the system.

e. Controls and Thermostats: Regulate temperature, pressure, and other operational parameters.

f. Expansion Vessel: Compensates for the expansion of water as it heats up.

3. Working Principles of Boilers:

Boilers operate based on the principle of heat transfer. They use fuel combustion to generate heat, which is then transferred to the water or steam. The heated water or steam is then circulated through pipes and radiators, releasing heat into the surrounding space. The circulating water or steam returns to the boiler to be reheated, creating a continuous cycle of heat distribution.

4. Benefits of Boilers:

a. Efficient Heating: Boilers are known for their high energy efficiency, allowing precise control over temperature settings and reducing energy waste.

b. Comfort and Flexibility: Boilers offer comfortable and even heat distribution throughout the building, allowing for zoned heating and customized temperature control in different areas.

c. Hot Water Supply: Boilers with integrated hot water cylinders provide ample hot water for bathing, washing, and other household needs.

d. Longevity: With proper maintenance, boilers have a long lifespan, providing reliable heating for many years.

5. Boiler Maintenance:

Regular boiler maintenance is crucial to ensure optimal performance and safety. Here are some maintenance tasks:

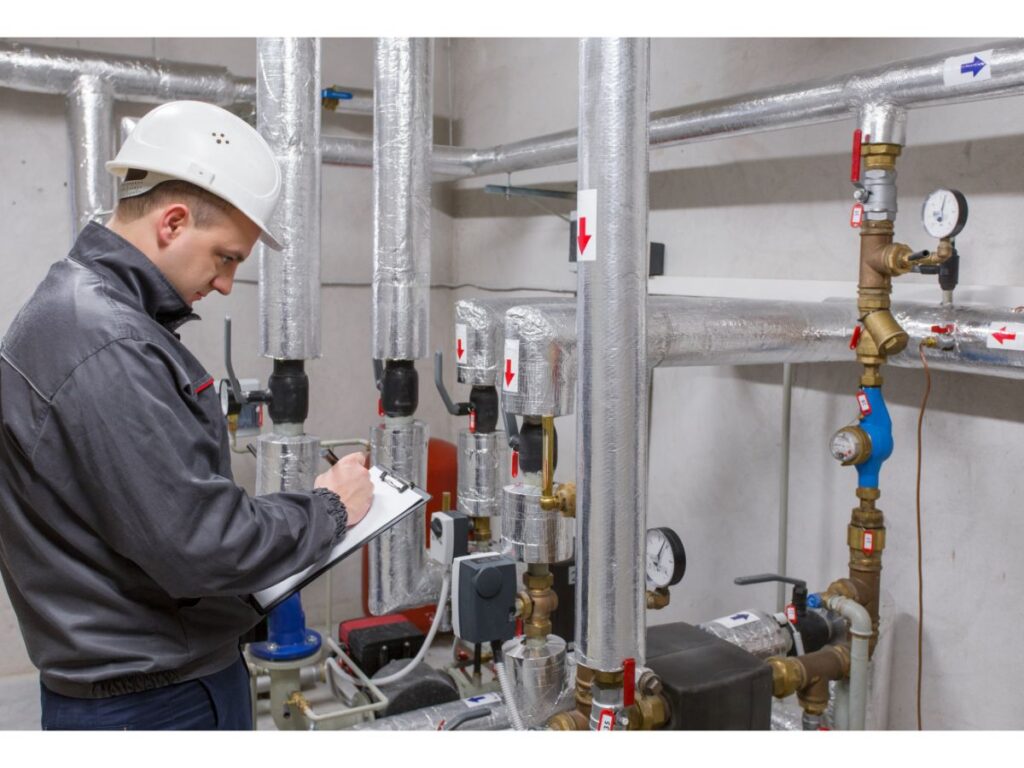

a. Annual Servicing: Schedule annual servicing by a qualified technician to check and clean the components, test safety features, and identify any potential issues.

b. System Flushing: Sludge and debris can accumulate in the system over time. Flushing the system helps maintain efficiency and prevent blockages.

c. Pressure and Safety Checks: Regularly check the boiler pressure, safety valves, and controls to ensure they are operating within safe limits.

d. Bleeding Radiators: If radiators have cold spots or are not heating evenly, bleeding the radiators can remove trapped air and improve efficiency.

6. Safety Considerations:

Boiler safety should be a top priority. Follow these guidelines:

a. Carbon Monoxide (CO) Detectors: Install CO detectors near boilers and other fuel-burning appliances to detect any leaks and ensure early warning of potential CO poisoning.

b. Ventilation: Ensure proper ventilation in the boiler room or area to allow the safe release of combustion byproducts.

c. Regular Inspections:

Engage professional technicians to conduct safety inspections and address any concerns promptly.

Understanding Boiler Pressure:

Boilers play a crucial role in heating systems, providing warmth and comfort in residential and commercial buildings. Among the various factors that contribute to a boiler’s efficient operation, maintaining the correct boiler pressure is of paramount importance. This comprehensive guide will delve into the concept of boiler pressure, its significance, factors affecting pressure levels, and practical tips for understanding and managing boiler pressure to ensure optimal performance.

What is Boiler Pressure?

Boiler pressure refers to the force exerted by the water or steam within a boiler system. It is a measure of the internal pressure that the boiler operates at to ensure efficient and safe operation. Boiler pressure is typically measured in units of pressure, like pounds per square inch (psi), bar, or kilopascals (kPa).

The pressure within a boiler is a critical parameter that needs to be monitored and controlled. Maintaining the correct pressure range specified by the manufacturer for optimal performance and safety is essential. The pressure level determines the temperature at which water boils, or steam is generated within the boiler. It, in turn, affects the heat transfer process and the distribution of heat throughout the heating system.

The ideal boiler pressure can vary depending on the specific boiler type, design, and intended application. To determine the appropriate pressure range for a particular model, it is typically recommended to consult the manufacturer’s guidelines or seek professional advice.

Too high or too low pressure can lead to various issues. Excessively high pressure can strain the system, causing leaks, valve failures, or even boiler breakdowns. On the other hand, low pressure can result in inadequate heat output, cold spots in radiators, or a complete shutdown of the heating system.

Maintaining the correct boiler pressure is crucial for achieving efficient heat transfer, preventing system malfunctions, ensuring safety, and extending the boiler’s lifespan. Regular monitoring of boiler pressure, adherence to the recommended pressure range, and timely adjustments or maintenance are essential to ensure the boiler’s optimal operation and the overall efficiency and safety of the heating system.

Importance of Maintaining Boiler Pressure

Boilers are vital components of heating systems, responsible for providing warmth and hot water in homes and commercial buildings. One critical aspect of boiler maintenance is the regular monitoring and maintenance of boiler pressure. Maintaining the correct pressure is essential for optimal performance, energy efficiency, and safety. In this article, we’ll delve into the importance of retaining boiler pressure and how it impacts the overall operation of heating systems.

1. Efficient Heat Transfer:

Proper boiler pressure ensures efficient heat transfer from the boiler to the heating system. When the pressure is within the recommended range, the water or steam can effectively carry heat to the radiators or underfloor heating pipes. This efficient heat transfer results in faster and more consistent heating, maximizing energy efficiency and reducing fuel consumption. By maintaining the correct pressure, you can achieve optimal heat output, providing comfort while minimizing energy waste.

2. Preventing System Malfunctions:

Maintaining the appropriate boiler pressure helps prevent system malfunctions and potential breakdowns. Excessively high pressure can strain the components, leading to leaks, valve failures, or even catastrophic failure. On the other hand, low pressure can cause inadequate heat output, cold spots in radiators, or a complete system shutdown. By ensuring the boiler operates within the recommended pressure range, you reduce the risk of unexpected failures and costly repairs.

3. Ensuring Safety:

Safety is of paramount importance to boiler operation. Excessively high pressure can lead to the release of steam or hot water, causing scalding or other injuries. Additionally, it can cause damage to the boiler and other system components. On the other hand, low pressure can result in the boiler flame going out, potentially leading to the buildup of flammable gases. Maintaining the correct pressure helps ensure the safe operation of the boiler and reduces the risk of accidents or hazardous situations.

4. Extending Boiler Lifespan:

Proper maintenance of boiler pressure can contribute to the longevity of the boiler. When the pressure is maintained within the recommended range, the boiler operates under optimal conditions, reducing stress on the system components. It leads to less wear and tear, prolonging the lifespan of the boiler. Regular monitoring and maintenance of boiler pressure, along with other routine servicing, can help identify and address any issues early on, preventing significant damages and increasing the overall lifespan of the boiler.

5. Efficient Hot Water Supply:

Boilers often provide hot water for domestic use in addition to heating. Maintaining the correct pressure ensures a consistent and reliable hot water supply throughout the building. Whether bathing, washing dishes, or other household needs, the appropriate boiler pressure ensures an ample and efficient hot water supply, enhancing the overall comfort and convenience of the occupants.

Factors Affecting Boiler Pressure:

Several factors can influence boiler pressure:

1. Heating Load: The demand for heat within a building affects the pressure requirements of the boiler. Higher heating loads may require higher pressures to meet the demand for hot water or steam.

2. System Design: Different heating systems and boiler types require specific pressure. Understanding the design specifications and recommended pressure range for your particular system is essential.

3. Expansion and Contraction: As water or steam heats up within the boiler and distribution pipes, it expands, increasing pressure. Conversely, as the system cools down, pressure decreases. This expansion and contraction should be accounted for in the boiler design and managed effectively.

Recommended Boiler Pressure Range:

The optimal boiler pressure range typically falls between 1.0 and 1.5 bar (14.5 to 21.7 psi) on the pressure gauge. However, different boiler models may have specific pressure requirements, so it’s always advisable to consult the manufacturer’s manual or seek professional guidance to determine the exact pressure range for your particular boiler.

Reasons for Pressure Fluctuations:

Boiler pressure can fluctuate for various reasons, and it’s essential to understand the causes and address them promptly. Some common reasons for pressure fluctuations include:

1. Heating System Expansion: As the water inside the heating system heats up, it expands, causing pressure to increase. Conversely, as the water cools down, the pressure decreases. These fluctuations are normal and are typically managed by the boiler’s pressure relief valve.

2. Leaks: Any leaks in the heating system can cause a drop in boiler pressure. Leaks can occur in pipes, valves, fittings, or even the boiler itself. Identifying and fixing leaks promptly is crucial to maintain optimal pressure levels and prevent further damage.

3. Faulty Pressure Relief Valve: The pressure relief valve is designed to release excess pressure to prevent the boiler from reaching unsafe levels. If the valve is faulty or blocked, it can cause pressure to build up beyond the recommended range.

Monitoring and Adjusting Boiler Pressure:

It’s essential to monitor and adjust the pressure as needed to ensure the boiler operates within the optimal pressure range. Here are the steps to follow:

1. Check the Pressure Gauge: Locate the pressure gauge on your boiler. It is typically located on the front panel or near the boiler controls. The gauge will display the current pressure level.

2. Ideal Pressure Range: Compare the pressure shown on the gauge to the recommended pressure range for your specific boiler. If the pressure is either too low or too high, adjustments are necessary.

3. Adjusting Pressure: If the pressure is too low, you will need to increase it. To do this, locate the filling loop (a flexible hose with a valve) connected to the boiler. Open the valve slowly to allow water into the system until the pressure reaches the desired level.

4. Bleeding Radiators: If the pressure is too high, it may be necessary to bleed excess air from the radiators. This process involves opening a small valve on each radiator to release trapped air until the pressure returns to the recommended range.

5. Seek Professional Assistance: If you are unsure about adjusting the pressure or if you notice persistent pressure fluctuations, it is best to consult a qualified heating engineer or technician. They can inspect the system, identify any underlying issues, and perform necessary repairs or adjustments.

Understanding the Right Boiler Pressure is Essential

In conclusion, understanding and maintaining the appropriate pressure is crucial for the efficient and safe operation of heating systems. The recommended pressure range typically falls between 1.0 to 1.5 bar (14.5 to 21.7 psi), but it’s essential to consult the manufacturer’s guidelines or seek professional advice specific to your boiler model.

By adhering to the correct pressure range, you can ensure optimal energy efficiency and consistent heat distribution, and prevent potential hazards associated with excessively high or low pressure. Regularly monitoring the pressure gauge, adjusting pressure when necessary, and promptly addressing pressure fluctuations or system issues will contribute to your boiler’s smooth and reliable operation.

Remember, when in doubt or if you encounter persistent pressure problems, it is always recommended to consult a qualified heating engineer or technician. Our boiler professionals here at Patriot Boiler have the expertise to assess your specific system, identify underlying issues, and provide appropriate solutions to maintain the ideal boiler pressure and keep your heating system operating at its peak.

By prioritizing proper boiler pressure, you can enjoy a comfortable and well-functioning heating system that efficiently provides warmth and hot water, enhancing your home’s overall comfort and safety.

Recent Comments