What Is a Heat Exchanger

A heat exchanger is a device used for transferring heat energy between two or more fluids or substances at different temperatures. It facilitates the efficient transfer of thermal energy from one medium to another without mixing them.

The key function of a heat exchanger is to maximize the exchange of heat while minimizing any physical contact or mixing of the fluids involved. Heat exchangers are commonly used in various industries and applications, including HVAC systems, power plants, chemical processes, refrigeration systems, and more.

The basic principle of a heat exchanger involves two fluid streams, often referred to as the “hot” fluid and the “cold” fluid. The hot fluid, which is at a higher temperature, transfers its heat to the cold fluid, which is at a lower temperature. This heat transfer occurs through a solid barrier or a heat transfer surface that separates the two fluids.

Types of Heat Exchanger

There are different types of heat exchangers, each designed to suit specific applications and operating conditions. Some common types include:

-

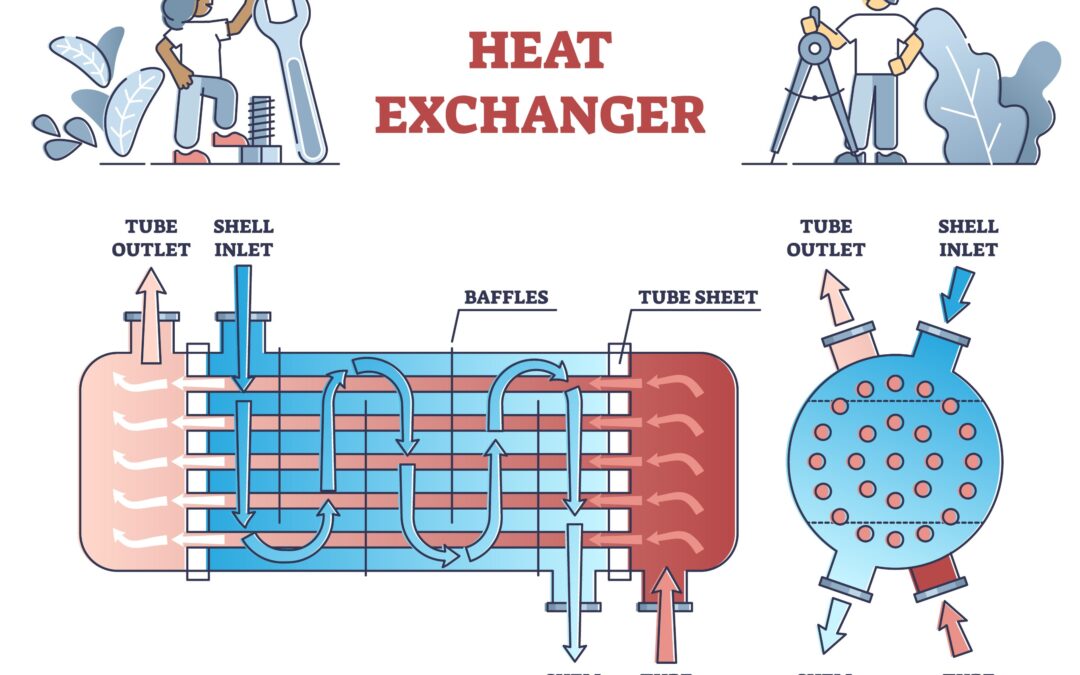

Shell and Tube Heat Exchanger

This type consists of a series of tubes enclosed within a cylindrical shell. One fluid flows inside the tubes (the tube-side fluid), while the other flows through the shell (the shell-side fluid). Heat is transferred from the tube-side fluid to the shell-side fluid through the tube walls.

-

Plate Heat Exchanger

Plate heat exchangers consist of a series of plates stacked together, forming alternating channels for the hot and cold fluids. The plates have large surface areas, promoting efficient heat transfer between the fluids.

-

Finned Tube Heat Exchanger

This type of heat exchanger has tubes with extended surfaces called fins. The fins increase the heat transfer area and enhance the efficiency of heat transfer between the fluids.

-

Plate-Fin Heat Exchanger

Plate-fin heat exchangers are compact and lightweight. Their core consists of stacked plates with alternating layers of fins. The plates create channels for the flow of hot and cold fluids, and the fins increase the heat transfer surface area.

Heat exchangers play a crucial role in various industrial processes and systems by efficiently transferring heat energy from one medium to another. They help conserve energy, improve process efficiency, control temperatures, and contribute to thermal systems’ overall performance and effectiveness.

Advantages of Heat Exchanger

Heat exchangers offer several advantages in various applications and industries. Here are some key advantages of using heat exchangers:

-

Efficient Heat Transfer

Heat exchangers are designed to maximize thermal energy transfer between fluids. They provide an efficient means of exchanging heat, allowing for effective temperature control and energy utilization. Heat exchangers help improve the efficiency of heating, cooling, and energy recovery processes by optimizing heat transfer.

-

Energy Conservation

Heat exchangers contribute to energy conservation by enabling the recovery and reuse of waste heat. They can extract heat from hot exhaust gases or process streams and transfer it to incoming fluids, reducing the need for additional energy inputs. It leads to significant energy savings and reduced operating costs.

-

Versatility

Heat exchangers are versatile devices that can be customized to befit specific applications and operating conditions. They can handle a vast range of temperatures, pressures, and flow rates, making them adaptable to diverse industrial processes. Additionally, heat exchangers can be constructed from various materials to accommodate corrosive or aggressive fluids.

-

Compact Design

Heat exchangers are typically designed to be compact, allowing for efficient use of space in installations. Their compact size enables easy integration into existing systems or equipment without requiring significant modifications or expansions.

-

Temperature Control

Heat exchangers enable precise control of fluid temperatures. They can heat or cool fluids to specific setpoints, ensuring consistent and reliable thermal management in industrial processes. It is vital in applications where maintaining precise temperatures is critical for product quality, safety, or operational requirements.

-

Reduced Fouling and Contamination

Heat exchangers can incorporate features that minimize fouling and contamination, such as specialized surfaces or turbulators. These features enhance heat transfer efficiency by reducing the accumulation of deposits or contaminants on the heat transfer surfaces. As a result, maintenance requirements are reduced, and system performance is maintained over extended periods.

-

Environmentally Friendly

Heat exchangers contribute to environmental sustainability by promoting energy efficiency and reducing greenhouse gas emissions. Heat exchangers help reduce the overall energy consumption and carbon footprint of industrial processes by recovering and utilizing waste heat.

Overall, heat exchangers provide numerous advantages, including efficient heat transfer, energy conservation, versatility, compact design, temperature control, reduced fouling, and environmental benefits. These advantages make heat exchangers essential components in various industries, enabling enhanced performance, cost savings, and sustainable operations.

Disadvantages of Heat Exchanger

While heat exchangers offer numerous advantages, there are also some potential disadvantages to consider. Here are a few drawbacks associated with heat exchangers:

-

Cost

Heat exchangers can be expensive to purchase, install, and maintain. The cost depends on factors such as the type of heat exchanger, materials used, size, and complexity. In some cases, the initial investment cost may be significant, especially for specialized or custom-designed heat exchangers. Additionally, ongoing maintenance and cleaning may add to the overall cost of ownership.

-

Fouling and Maintenance

Heat exchangers are susceptible to fouling, which refers to the accumulation of deposits or contaminants on the heat transfer surfaces. Fouling can reduce heat transfer efficiency, leading to decreased performance and increased energy consumption. Regular maintenance, cleaning, and periodic inspection are necessary to prevent or mitigate fouling issues. It adds to the operational and maintenance requirements of heat exchangers.

-

Pressure Drop

Heat exchangers can introduce pressure drop in the fluid flow due to the design and flow resistance within the exchanger. Higher pressure drops can lead to increased pumping costs or affect the overall system performance. Careful consideration of the heat exchanger design and its impact on the system’s pressure requirements is necessary.

-

Compatibility and Corrosion

Heat exchangers handle various fluids, and compatibility between the heat exchanger material and the fluids being processed is essential. Some fluids may be corrosive, leading to degradation or damage to the heat exchanger surfaces. Selecting the appropriate material for the specific application is crucial to avoid compatibility issues and corrosion-related problems.

-

Size and Space Requirements

Depending on the heat transfer requirements and flow rates, heat exchangers can be relatively large. This can pose challenges in installations where space is limited. In some cases, modifications or additional equipment may be required to accommodate the heat exchanger’s size, leading to increased costs and complexity.

-

Efficiency Limitations

While heat exchangers are designed for efficient heat transfer, their performance has practical limitations. Factors such as temperature differences, flow rates, fouling, and design constraints can affect their overall efficiency. It’s essential to carefully consider the specific application requirements and select an appropriate heat exchanger design to achieve desired performance levels.

Despite these disadvantages, heat exchangers remain widely used due to their capability to transfer heat in various industrial processes efficiently. By understanding and addressing these limitations, such as through proper maintenance, material selection, and system design considerations, the drawbacks associated with heat exchangers can be minimized, allowing for effective heat transfer and energy management.

Important Considerations for Heat Exchangers

When considering the use of a heat exchanger, there are several important factors to take into account. These considerations will help ensure the successful implementation and operation of the heat exchanger within your specific application. Here are some key points to consider:

-

Heat Transfer Requirements

Determine your application’s heat transfer requirements, including the desired temperature change, flow rates, and heat load. Understanding the specific thermal needs will help you select the appropriate type, size, and design of the heat exchanger.

-

Fluid Compatibility

Assess the compatibility of the fluids involved in the heat transfer process with the materials used in the heat exchanger. Ensure that the materials are resistant to corrosion, erosion, and other potential forms of degradation caused by the fluid properties.

-

Heat Exchanger Type

Select the most suitable type of heat exchanger for your application. Consider factors such as efficiency, pressure drop, fouling tendencies, space availability, and maintenance requirements. Common types include shell and tube, plate, finned tube, and plate-fin heat exchangers, each with its own advantages and limitations.

-

Size and Capacity

Determine the appropriate size and capacity of the heat exchanger based on the heat transfer requirements and fluid flow rates. Consider the available space for installation and any constraints on dimensions or weight. Oversizing or undersizing the heat exchanger can lead to inefficiencies and performance issues.

-

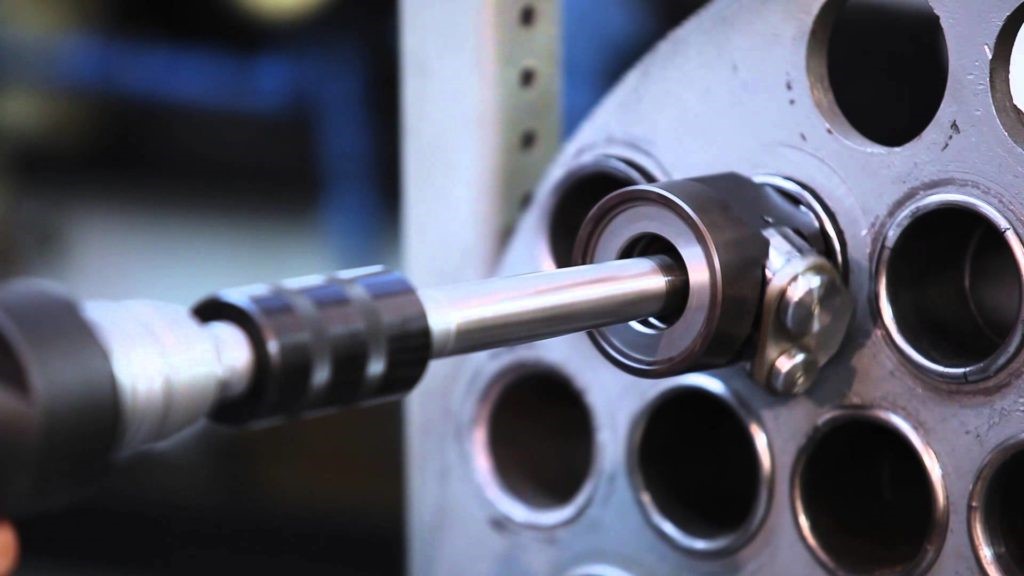

Maintenance and Cleaning

Understand the maintenance requirements of the heat exchanger and ensure that you can implement proper cleaning procedures. Some heat exchangers may require periodic cleaning to prevent fouling and maintain optimal performance. Consider accessibility for maintenance activities and the associated costs.

-

Energy Efficiency

Assess the heat exchanger’s energy efficiency. Look for features such as enhanced heat transfer surfaces, optimal flow patterns, and efficient design to minimize energy losses and maximize heat transfer effectiveness. Energy-efficient heat exchangers can contribute to cost savings and environmental sustainability.

-

System Integration

Consider how the heat exchanger will integrate into your existing system or process. Evaluate compatibility with other equipment, such as pumps, valves, and control systems. Ensure that the heat exchanger can be seamlessly integrated into the overall system without causing disruptions or inefficiencies.

-

Regulatory Compliance

Be aware of any relevant regulations, codes, and standards that apply to the specific industry or application. Ensure that the heat exchanger design and installation comply with safety and environmental requirements.

-

Lifecycle Cost

Consider the heat exchanger’s lifecycle cost, including initial investment, installation, maintenance, and operational expenses. Compare different options and evaluate their long-term cost-effectiveness to make an informed decision.

By carefully considering the factors above, you can select and implement a heat exchanger that meets the specific needs of your application while maximizing efficiency, reliability, and overall performance. Consulting with experts and professionals in the field of heat exchangers can also provide valuable insights and guidance throughout the selection and implementation process.

Why Heat Exchangers are Beneficial for Industries

The use of a heat exchanger can be highly beneficial in many applications and industries. Here are some reasons why heat exchangers are often recommended:

1. Efficient Heat Transfer

Heat exchangers are designed to maximize thermal energy transfer between fluids, resulting in efficient heat exchange. It can improve energy efficiency, reduce operating costs, and enhance overall system performance.

2. Energy Conservation

Heat exchangers allow for the recovery and reuse of waste heat, reducing the need for additional energy inputs. By extracting heat from hot streams and transferring it to colder streams, heat exchangers contribute to energy conservation and can lead to significant energy savings.

3. Temperature Control

Heat exchangers enable precise temperature control by transferring heat between fluids at different temperatures. It is crucial in applications where maintaining specific temperature levels is essential for product quality, safety, or operational requirements.

4. Versatility

Heat exchangers are available in various designs, sizes, and materials to suit different applications and operating conditions. They can handle a vast range of temperatures, pressures, and flow rates, making them versatile for use in diverse industries and processes.

5. Space Optimization

Heat exchangers are often designed to be compact, allowing for efficient use of space in installations. It is particularly beneficial when space is limited or when retrofitting existing systems.

6. Environmental Benefits

Heat exchangers contribute to environmental sustainability by minimizing energy consumption and greenhouse gas emissions. Heat exchangers help minimize the carbon footprint and promote a more sustainable operation by recovering waste heat and improving energy efficiency.

However, it is important to consider your application’s specific requirements and evaluate factors such as cost, maintenance needs, compatibility with fluids, and system integration. Consulting with experts in the field of heat exchangers can provide you with more specific guidance based on your unique needs.

In summary, heat exchangers are generally recommended due to their ability to efficiently transfer heat, conserve energy, provide temperature control, offer versatility, optimize space, and contribute to environmental sustainability. Assessing your specific requirements will help determine whether a heat exchanger is the right choice for your application.

Get Reliable Help from Professionals

In conclusion, heat exchangers are valuable devices that facilitate efficient heat transfer in various industrial processes and applications. You can make informed decisions when using heat exchangers by considering key factors such as heat transfer requirements, fluid compatibility, heat exchanger type, size and capacity, maintenance, energy efficiency, system integration, regulatory compliance, and lifecycle cost.

Heat exchangers offer numerous advantages, including energy conservation, precise temperature control, versatility, compact design, and reduced fouling and contamination. They play a crucial role in optimizing thermal management, improving process efficiency, and reducing operational costs. However, it is critical to be aware of the potential disadvantages associated with heat exchangers, such as cost, fouling, pressure drop, compatibility and corrosion issues, size requirements, and efficiency limitations.

Heat exchangers can be successfully implemented and integrated into your system with careful consideration of these factors and addressing potential challenges. Proper selection, maintenance, and operation of heat exchangers are essential to ensure optimal performance, longevity, and cost-effectiveness.

It is recommended to consult with experts or professionals in heat exchanger technology and seek their guidance throughout the decision-making and implementation process. With the right considerations and proper utilization, heat exchangers can significantly contribute to efficient heat transfer, energy savings, and overall process enhancement in various industries. Contact Patriot Boiler for your heating needs today!

Recent Comments