What Is a Boiler Room

The boiler, of course. Boilers are installed in some homes to provide hot water for drinking, hot water for heating, or both. These are often older homes that heat using radiators rather than forced air.

Homes with steam boilers for heating are less frequent. With a radiant heating system, water heats to almost boiling point in a boiler before being sent through linked pipes to the radiators, which radiate heat into the rooms. The water inside of this isolated system is unfit for human consumption.

The second piece of equipment requires a closed boiler system to provide the house with potable hot water. You will need a typical residential water heater that is put in the boiler room with the boiler unless a tankless system is installed.

In an open system, a boiler warms the water when a person turns on the hot faucet at the sink or the shower while also providing water to the radiators. The water then exits the boiler through the tap after traveling through the pipes. Boilers do not hold hot water in storage as water heaters do.

The boiler room generates hot water or, less frequently, steam to heat household water and the structure.

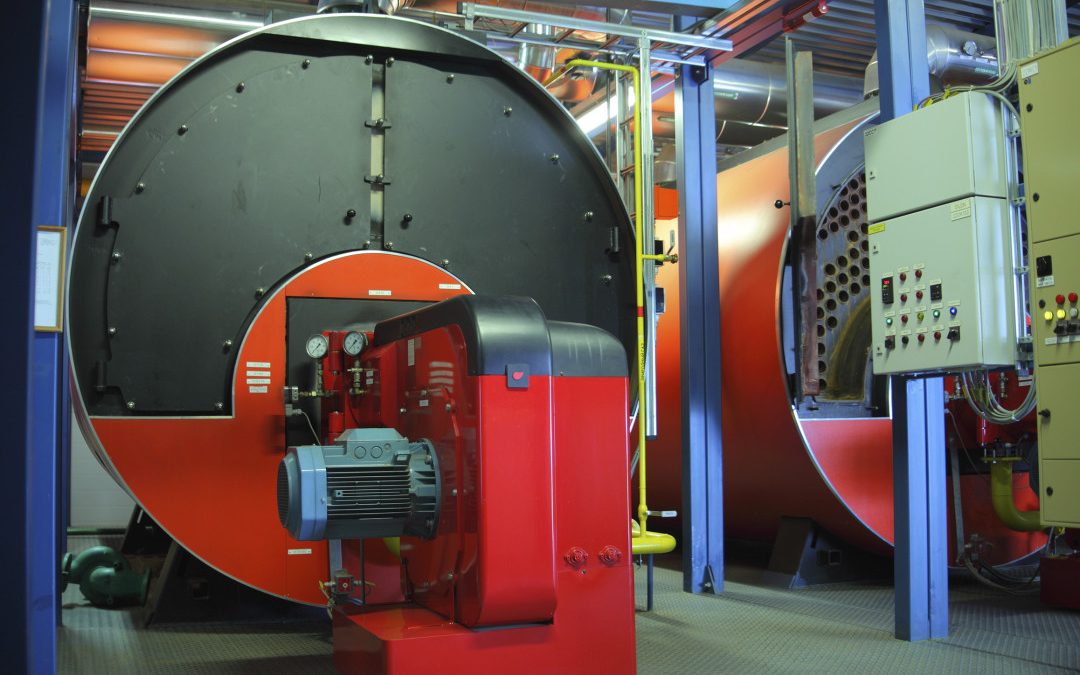

Steam is occasionally used utilized to power absorption cooling machinery. A big building’s boiler room typically houses two or more boilers so that people may use one while another is being cleaned or repaired. One chimney serves as the connection for all boilers. Boiler rooms can be located anywhere in a structure. Typical spots include the roof, mechanical floor, basement, and mechanical room on grade. Due to the necessity for an intake grille for combustion air and a door or detachable panel to facilitate the removal and replacement of boilers, it should be mounted on an outside wall.

A boiler room should be located underneath or close to places like loading docks and lobbies. These are places that won’t be negatively impacted because of the noise and heat it produces. The boiler room should be close to the chilled water plant since the two facilities frequently merge into one space. Vertical shafts connect the boilers’ hot water supply and return pipes to the building’s other levels.

When planning the supporting structure, floor loadings caused by boilers and related machinery must be considered.

Gas, electricity, or oil can all be used to power boilers. The necessity for combustion air inlets and a chimney is removed by electric boilers, which are often only cost-effective in locations with meager power rates. Fuel for an oil-fired boiler is usually kept in tanks within or close to the building for a two-week supply. Oil delivery trucks must have access to the filling pipelines. These tanks are often buried near the structure if there is enough room. If the tanks are within the building, they must be situated in a naturally ventilated space. It is intended to hold a tank’s entire contents while preventing them from leaking outside the structure.

The best site is on an outside wall in the basement.

Oil is pumped through a conduit from the tanks below to a boiler on an upper story of the structure.

A boiler room’s approximate floor space may be calculated using the chart on pages 190–191. A long, thin room is typically preferred over a square one in more significant structures. A boiler room’s ceiling height might range from 12 feet (3.66 meters) for a small form to 16 feet (4.88 meters) for a big one.

The chimney’s height, the kind of draft (natural, forced, or induced), and other factors all affect the duct size connected to fuel-burning boilers. Allow a floor space for a vent of 2 feet by 2 feet (610 mm square) for a very tiny structure and 6 feet by 6 feet (1.83 m square) for a massive building for primary design reasons. For installations of various sizes, interpolate between these extremes. Remember that the chimney above the boiler room passes through each structure story.

Recent Comments