Boilers are vital vessels with multiple industrial and household applications. Their primary function is to generate steam.

The boiler comprises numerous sections or serves as a support system for the boiler to create the desired quantity of steam or heat. Water and steam are transported throughout the system via tubes. Soot blowers also blast air or steam water into the boiler to keep fly ash or particles clear. Economizers collect heat from the exit gas and pre-heat the water required to generate steam, while burners burn the fuel (gas, coal, oil, or waste). In addition, many other related systems, such as insulation, brick, refractory, and lagging, contribute to the energy of the steam boiler.

Furthermore, boilers require feedwater before they can create steam. Boiler feed pumps deliver high-pressure feedwater from the deaerator tank to the boiler. It is an essential unit of the entire boiler system.

What Is a Boiler Feed Pump

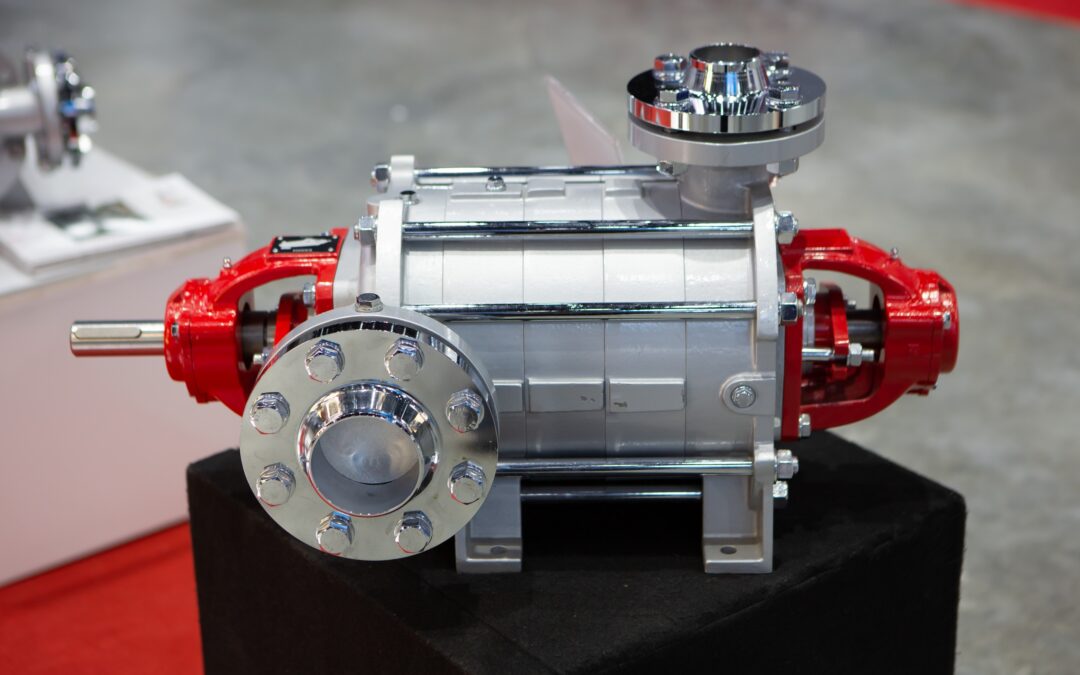

A boiler feed pump is used to supply high-pressure water to a steam boiler. Such pumps intend to resist high intake pressures while producing substantial differential pressures via a multistage or side channel pump design. Suction is drawn from a condensate system, and the pumps required are typical of the high head low flow variety. They often use ductile iron, stainless steel, or duplex due to the high pressures in such pumps.

Furthermore, boiler feed pumps provide a quantity of feedwater equivalent to the steam generated by a steam generator. A boiler designer calculates the boiler feed water’s operating parameters (head, flow, and temperature).

Almost all boiler feed pumps nowadays are centrifugal pumps. The advancement of power technology has dictated the creation of BFPs in terms of material, shaft power, pump types, and drive. The trend in fossil fuel power plants is toward bigger power block units.

Its Construction and Operation

Feedwater pumps can be many kilowatts in capacity, with the electric motor generally isolated from the pump body by some mechanical linkage. Large industrial condensate pumps might potentially be used as feedwater pumps. In any instance, the pump must create enough pressure to overpower the steam pressure generated by the boiler to drive water into the boiler.

Furthermore, they typically use a centrifugal pump to do this. Another typical type of feedwater pump works continuously and has a minimum flow mechanism to prevent the pump from over-pressurizing on low flows. Typically, the minimal flow returns to the tank or deaerator.

Mechanical Seal Failure

Mechanical seals on the boiler feedwater pump frequently exhibit electrical deterioration. Because the boiler water has a very low conductivity, the relative movement between the fixed ring and sliding ring causes a static charge, which is not redirected. Pieces the size of fingers break off from the sliding and/or stationary rings during short durations of operation – in some cases, only a few hundred operating hours – causing fast increases in leakage current. Diamond-coated (DLC) mechanical seals prevent this issue and significantly increase durability.

Its Maintenance

Feed pump maintenance is usually inexpensive. It requires occasional bearing lubrication, seal replacement, and regular checking of float level controls. Finally, look for leaky pipework, which may be caused by corrosion in the system.

Its Redundancy

A boiler must have access to the water, and it needs to function correctly. If you reduce the flow, you will have a low water condition. When you increase flow, you get carryover. As a result, most systems will have redundancy.

Furthermore, you must switch between these pumps frequently as a boiler operator. This helps to ensure that pumps do not lock up when slitting idle for an extended time. It will also aid you in identifying a problem before it becomes an emergency.

Feed Pump Operation in a Boiler Feed System / Steam Turbines

The feed pump raises the pressure of the feedwater so that it may enter the boiler. A steam-driven reciprocating positive displacement pump can be used in auxiliary boilers to pump modest volumes of feedwater.

An electro-feeder is another form of feed pump that they frequently employ on package boiler systems. It is a multistage centrifugal pump powered by an electric motor at a constant speed. The number of stages is governed by the amount of feed and the discharge pressure.

Furthermore, steam turbine-driven feed pumps are standard with high-pressure water tube boiler systems. The impulse turbine powers the two-stage horizontal centrifugal pump with the entire unit housed in a single casing.

Types of Boiler Feed Pumps

The majority of boiler feed pumps are multistage. They employ many impellers in sequence to achieve the high pressures required to feed the boiler. Bearings on either end of the pump shaft support the pump shaft, sometimes referred to as a Between-Bearing Pump (BB Pump). The impellers are located in the space between the bearings.

These multistage pumps are classified as vertical or horizontal. The direction of their shafts determines their categorization. Both pumps are radially separated and have a vertical junction relative to the shaft in the casing.

The pressures that these boiler feed pumps can create are a substantial difference.

Vertical Pumps

The vertical pumps are stamped stainless steel constructed.

These pumps demand more excellent vertical space but take up less floor area. They can endure higher pressures and temperatures than horizontal pumps. These pumps are also far more difficult to repair due to their design.

Horizontal Pumps

On the other hand, the horizontal pumps are heavy-duty pumps with cast-iron components.

These pumps are often less challenging to maintain and install than their vertical counterparts. This is primarily because their core components are easier to access. While this is a significant advantage, the horizontal arrangement requires more floor space in a boiler room. These pumps generally have a maximum pressure of 1500 PSIG, which is moderately lower than vertical pumps.

Pumps and Feedwater

They built feed pumps to withstand the high temperatures of boiler systems. At atmospheric pressure, steam turns by water at 212 degrees Fahrenheit. On the other hand, water will remain liquid at greater temperatures if you pressurize the deaerator. It implies they built specific pumps to withstand temperatures ranging from 225 to 350 degrees Fahrenheit.

Furthermore, they often made pumps out of ductile iron or stainless steel. You may choose one over the other depending on the chemical compounds in the water. Using the incorrect material might cause corrosion on pump components over time.

Modulating Continuous vs. On/Off Continuous Feed Pumps

Modulating continuous pumps uses more complicated controls to shift the feedwater valve from open to closed, depending on the steam rate. These pumps can produce more consistent water levels and are less likely to cause heat shock. They also reduce the wear and tear caused by repeatedly turning on and off. Modulating continuous pumps, on the other hand, are substantially more expensive to build. This is because of the added controls, pipelines, valves, and larger motors.

The low water cutoff float activates on/off pumps. An electrical signal is sent to the pump as the float falls, causing it to turn on. Because of their simplicity, these systems are less expensive and easier to install than modulating systems. The temperature difference between the boiler and the feedwater might be a concern due to these pumps’ on/off nature. Because the water is pushed in all at once, thermal shock might occur, producing problems with the metal in the surrounding region. Furthermore, starting and stopping causes excessive wear and tear on the pump and causes a fluctuating water level.

Pressure Requirements

You can use the following list of pressure drops when determining the discharge head for a pump:

The Total Pump Discharge Pressure must be more than:

System Pressure

The pressure needed by the steam distribution system is called the system pressure.

Economizer

The pressure decreases over the economizer’s waterside.

Non-Return Valve Loss

It is the amount of drop that happens across the non-return valve. The boiler must run high enough pressure to overcome this and meet the system pressure requirements.

Super Heater

The pressure decreases over the super heater’s waterside.

Modulating Level Control Valve

The pressure decreases across the level control valve. It is not necessary with on/off pump control.

Piping Loss to Boiler Height

The drum may be significantly higher than the boiler feedwater pumps. The pumps must raise the water level to the drum level.

Feed Stop and Check Loss

The distance between the feedwater stops and check valves.

Total Discharge Pressure

The total of all pressure dips that the feed pump must meet. To pick the pump, you must translate the total pressure drop to the feet of the discharge head. You can convert PSIG to feet of the head using a correction factor of 2.31. By dividing the head by 0.96, we account for the density of boiling water, 227 degrees Fahrenheit.

Getting and Staying Warm

Transient or low-flow operating circumstances cause additional demands on boiler feed pumps. It causes extra loads, strains, and component deformation, with varying effects on functionality.

Almost all boiler feed pumps must withstand cold beginnings (high-temperature shock loads) and semi-warm starts without harm. During these start-up operations, hot feed water surges abruptly into the cold pump, causing the inner components to heat up significantly quicker than the pressure boundary. Depending on the frequency of starts and the gradient curves of pressure and temperature or load cycles, this can reduce the pump’s service life.

Heat will spread slowly in thick-walled components on machines with exceptionally thick walls, causing internal tensions.

Rotor and Stator

Contact between rotor and stator parts cannot be ruled out because narrow clearances are used as controlled gap seals. This applies to the neck’s impeller on the impeller inlet side, the discharge-side clearance between the diffuser, impeller, and interstage bush, and the balancing device with several throttling clearances.

Critical operational situations in the input line, such as the development of vapor bubbles, cannot be prevented. In tight clearances, brief contact between the rotor and the stator causes substantial imbalance forces. As a result, the material pairings must be resistant to erosion, corrosion, and wear. Profiled chrome steels and a unique clearance geometry have proven effective.

Temperature layers occur in the fluid handled during operating situations with very low or zero flow, such as in the turning gear mode of a turbine-driven boiler feed pump, causing deformation of the rotors and, after a little delay, also of the non-rotating components. When the clearance gaps are closed, the rotor is subjected to a much larger friction moment, resulting in an overload of the pump stoppage and turning gear. In this circumstance, the temperature at the rotor will no longer be equalized, exacerbating the rotor deformation.

It can cause the pump to be shut off for several hours. Typically, the sole solution is to allow the machine to cool down to lessen or eliminate the critical temperature deformation and layers.

Selecting the Right Boiler Feed Pump

One of the most vital factors to assess when selecting a pump is that it can overcome the pressure in the boiler. Then, depending on your system, you must achieve particular net positive suction head criteria. It is crucial because your pump will cavitate if it is not fulfilled.

Cavitation happens when a pump’s liquid converts to vapor at low pressure. It occurs when there is not enough pressure at the pump’s suction end or insufficient Net Positive Suction Head (NPSHa) available.

Furthermore, cavitation is the formation of low-pressure air bubbles. The bubbles collapse when the liquid moves from the impeller’s suction side to the delivery side. It produces a shockwave that strikes the impeller, causing pump vibration and mechanical damage, possibly resulting in total pump failure at some point.

In addition to causing damage from air bubbles, this can generate vibration in the system. Vibration can also cause pump failure, which can cause additional mechanical concerns.

Next, examine whether a vertical or horizontal pump suits your facility’s floor area better. Next, determine the appropriate head and flow rate for each pump. Finally, select whether your facility requires an on/off feed pump or a modulating continuous feed pump. Eventually, choosing the right pump for your application might involve several aspects and should be done with the aid of an expert.

Make Your Operation Run Smoothly

At Patriot Boiler, we strive for perfection by offering installation, high-quality technical sales, and servicing. We also provide quality sounds, outstanding service, and timely prices to satisfy our customers’ demands.

We are all dedicated to maintaining company integrity and honesty through hard work, communication, and civility. Our staff strives to surpass all client expectations by offering outstanding goods and services. Give us a call now!

Recent Comments