A boiler is a closed container or vessel designed to heat water or generate steam, typically for heating systems or industrial processes. The heated or vaporized fluid produced by the boiler can be used for various applications, including space heating, water heating, power generation, and industrial processes.

Boilers operate by burning a fuel, such as natural gas, oil, or biomass, to produce heat. The heat transfers to the water or steam within the boiler, and the resulting hot water or steam then circulates to provide heating or other energy-related functions. Boilers are a vital component of many heating systems, ranging from residential heating systems to large-scale industrial facilities.

Types of Boilers

There are several types of boilers, each with its specific design and applications. The main types include:

1. Fire-Tube Boilers

Fire-tube boilers have tubes containing hot gases that transfer heat to the surrounding water. This type is typical for heating buildings and smaller industrial applications.

2. Water-Tube Boilers

Water-tube boilers have tubes full of water that are heated by combustion gases flowing around them. They are often used in large industrial and power generation applications.

3. Steam Boilers

Steam boilers produce steam, which can be used for various purposes, such as power generation, heating, and industrial processes.

4. Hot Water Boilers

Hot water boilers produce hot water for heating buildings, providing domestic hot water, or other applications where hot water is essential.

5. Condensing Boilers

Condensing boilers are designed to recover heat from the flue gases, increasing efficiency. They are also common for residential and commercial heating systems.

6. Electric Boilers

Electric boilers utilize electricity to heat water or produce steam. They are also more common in areas where other fuel sources are impractical.

7. Combination Boilers (Combi Boilers)

Combination boilers combine the functions of a water heater and a central heating boiler. They provide both hot water for domestic use and space heating in a single unit.

Boilers provide heat for residential, commercial, and industrial applications. Proper maintenance and regular inspection are crucial to ensure boilers’ sound and efficient operation. Additionally, boilers are subject to safety regulations and standards to prevent accidents and ensure the protection of both people and property.

How to Install a Boiler

Boiler installation is a complex process that qualified professionals should carry out to ensure safety, efficiency, and compliance with local building codes. Here is a general overview of the steps to install a boiler:

1. Site Assessment

To determine the best location for the boiler, a complete assessment of the installation site is conducted. Factors such as available space, ventilation requirements, and proximity to gas or fuel sources are also considered.

2. Boiler Selection

The appropriate type and size of the boiler to install are selected based on the property’s heating requirements or application. Consequently, the choice may depend on factors like the requisite heating capacity, fuel type (gas, oil, electric), and the necessary features.

3. Permitting and Compliance

Obtain any necessary permits from local authorities before starting the installation. Additionally, compliance with building codes and relevant regulations is vital to ensure the safety and legality of the installation.

4. Gas and Electrical Connections

For gas boilers, a certified gas fitter will connect the boiler to the gas supply. Electrical connections are also made to power the boiler and its components. These connections must comply with safety standards.

5. Ventilation Installation

Adequate ventilation is critical for the safe operation of the boiler. Installing proper venting systems is essential to ensure the efficient removal of combustion byproducts, including carbon monoxide. Ventilation requirements also vary depending on the type of boiler and fuel used.

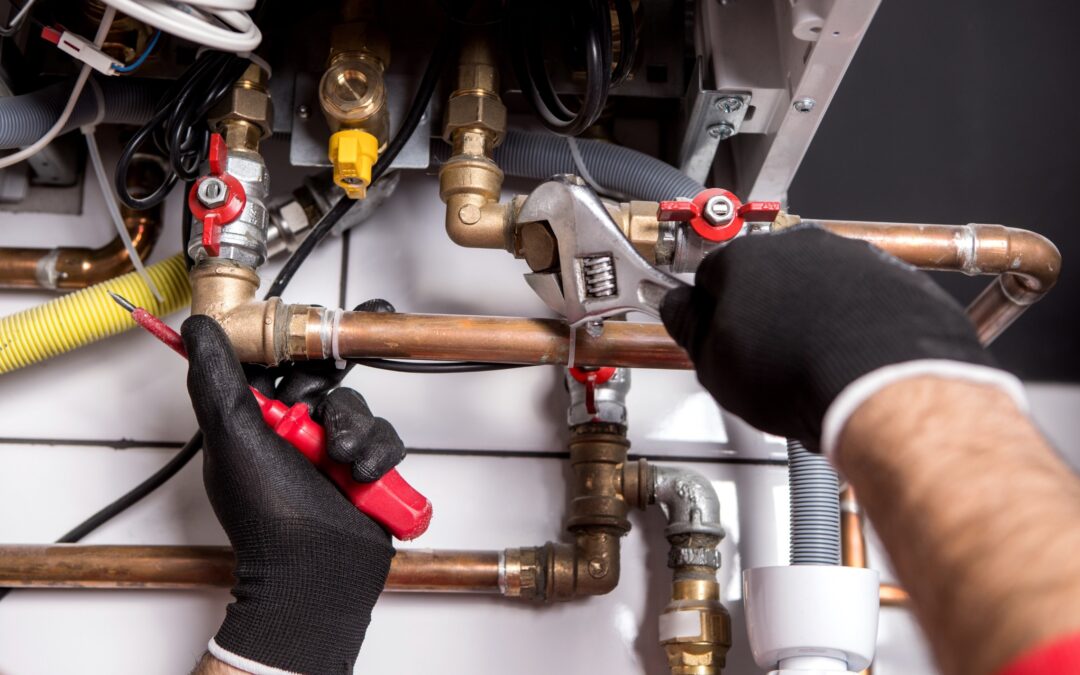

6. Water Piping Installation

The installation of water piping includes connecting the boiler to the heating system. It involves running pipes to and from the boiler and installing valves, pumps, and other components necessary for the heating distribution system.

7. Flue Installation

A flue system is installed to expel combustion gases safely. This system includes a flue pipe that directs gases from the boiler to the exterior. It must be appropriately sized and installed according to the manufacturer’s specifications and local codes.

8. Boiler Mounting

The boiler is securely mounted in its designated location. It may involve attaching the boiler to a wall or placing it on a stable platform. Proper mounting is crucial for stability and safety.

9. Expansion Tank and Pressure Relief Valve Installation

Then, you’ll need to install the boiler expansion tank to accommodate variations in water volume as it heats and cools. Additionally, a pressure relief valve is installed to release excess pressure from the system, ensuring its safety.

10. Control Wiring

Control wiring is installed to connect the boiler controls, thermostats, and safety devices. This wiring allows for the regulation of the boiler’s operation and ensures safe and efficient performance.

11. Fill and Purge System

The heating system fills with water, and air is purged from the system to prevent airlocks. Proper system filling and purging are essential for the efficient operation of the boiler and heating distribution.

12. Startup and Testing

Once the installation is complete, the boiler undergoes a startup procedure. It includes testing the boiler’s operation, checking for leaks, and ensuring all safety features function correctly.

13. Documentation and Compliance Verification

Proper documentation of the installation is provided, including user manuals, warranty information, and compliance certificates. The installation is also verified to ensure that it meets all safety and regulatory requirements.

It’s important to note that it is best to have licensed and experienced boiler professionals install your boiler system. Moreover, DIY installation may be impractical due to the potential risks associated with gas and electricity and the complex nature of boiler systems. Therefore, it is always best to conform to local building codes and regulations and consult with professionals for a safe and reliable boiler installation.

Boiler Operation Overview

A boiler’s operation involves converting fuel into heat, which is then transferred to water or steam. Then, the heated water or steam is used for various applications, like space heating, domestic hot water, or industrial processes. The specific workings of a boiler can vary based on its type and design, but the fundamental principles are generally similar. Here’s a basic overview of how a boiler works:

1. Fuel Combustion

The process begins with the combustion of a fuel source. Common fuels include natural gas, oil, coal, and biomass. The fuel burns in the combustion chamber, generating high-temperature gases.

2. Heat Transfer

The resulting heat after combustion transfers to the water or steam within the boiler. This heat transfer transpires through the walls of tubes or passages that come into contact with the hot combustion gases. The type of boiler (fire tube, water tube, etc.) determines the configuration of these passages.

3. Water Circulation (For Water-Tube Boilers)

In water-tube boilers, the heated water circulates through tubes within the boiler. The tubes may be arranged in various configurations, and the water absorbs heat from the combustion gases surrounding the tubes.

4. Steam Generation (For Steam Boilers)

In boilers designed to produce steam, the water absorbs heat and reaches a temperature where it transforms into steam. The steam can then be utilized for heating or to perform work in industrial processes.

5. Hot Water Production (For Hot Water Boilers)

For boilers producing hot water, the heated water circulates through a system of pipes to provide heating for buildings or other applications requiring hot water.

6. Pressure Regulation

Boilers operate under controlled pressure conditions. The boiler regulates pressure to ensure safe and efficient operation. In steam boilers, the pressure is critical for the proper functioning of steam-based systems.

7. Combustion Gas Exhaust

After transferring heat to the water or steam, the combustion gases exit the boiler through a flue or chimney. In some modern boilers, especially condensing boilers, efforts are made to recover additional heat from these gases before they are expelled.

8. Safety Features

Boilers are geared with safety features to prevent unsafe conditions. These may include pressure relief valves, temperature controls, and water level indicators. Safety is a crucial aspect of boiler operation to deter accidents and protect both people and property.

9. Control System

Boilers are equipped with control systems to regulate various aspects of their operation, such as fuel input, temperature, and pressure. Modern boilers often incorporate advanced control systems for optimal efficiency and performance.

The specific details of a boiler’s operation depend on its type, design, and intended application. Additionally, regular maintenance and strict compliance with safety standards are vital to ensure boilers’ reliable and safe operation. It’s also important to note that the efficiency of a boiler can be influenced by factors such as proper sizing, insulation, and combustion optimization.

Various Boiler Applications

Boilers primarily heat water or generate steam, and they are useful for various applications across residential, commercial, and industrial settings. The heat from boilers transfers to the water, which then circulates to provide warmth or perform specific tasks. Here are common applications of boilers:

1. Space Heating

Boilers are popular for space heating in residential, commercial, and industrial buildings. They can heat water, which then circulates through radiators, baseboard heaters, or underfloor heating systems to warm indoor spaces.

2. Domestic Hot Water

Boilers provide hot water for domestic use, including bathing, showering, washing dishes, and other household activities. Water is heated in the boiler and then stored in a water heater or circulated directly to taps and fixtures.

3. Industrial Processes

Many industrial processes require high-temperature water or steam. Boilers play an essential role in providing the necessary heat for processes such as manufacturing, chemical production, food processing, and more.

4. Power Generation

Boilers are also a key component in power plants for generating electricity. The heat from the boiler converts water into steam, which drives the turbines connected to generators.

5. District Heating

In some urban areas, boilers are essential for district heating systems, where a central boiler facility provides heat to several buildings through a network of pipes.

6. Laundry and Dry Cleaning

Boilers are also essential in laundry and dry cleaning facilities where steam is often requisite for pressing, ironing, and other textile processing operations.

7. Hospitals

Hospitals install boiler systems for a range of applications, including space heating, sterilization of medical equipment, and providing hot water for various needs within the healthcare facility.

8. Breweries and Distilleries

Boilers play a critical role in the brewing and distilling industries. They are useful for processes such as mashing, boiling, and pasteurization during the production of beer and spirits.

9. Greenhouses

Greenhouses use boilers to provide the necessary heat to maintain optimal temperatures for plant growth. They contribute to creating a controlled environment for crops.

10. Food Processing

The food industry utilizes boilers for cooking, pasteurization, sterilization, and other processes that require high-temperature water or steam.

11. Textile Industry

Boilers are integral to the textile industry for applications such as dyeing, drying, and fabric finishing. Steam generated by boilers is often used in textile processing.

12. Oil and Gas Exploration

Boilers are employed in oil and gas exploration for processes such as steam injection to enhance oil recovery.

13. Paper and Pulp Industry

Boilers are useful in the paper and pulp industry for various processes, including drying paper, producing steam for power generation, and chemical processing.

14. Chemical Processing

Chemical plants also use boilers for heating, reaction processes, and steam generation for various chemical production operations.

15. Automotive Industry

Boilers are essential in the automotive industry for processes such as metal forming, painting, and curing in the manufacturing of vehicles.

The versatility of boilers makes them essential in numerous industries and applications where reliable and efficient heat generation is necessary. The type and design of boilers can vary based on the particular needs of each application.

Boilers offer numerous advantages, making them a popular choice for heating in various settings. One significant benefit is their efficiency in providing consistent and even heating throughout a space. Boilers distribute heat through radiators, baseboard heaters, or underfloor heating systems, ensuring comfortable and uniform warmth. Boilers are also known for their durability and reliability, with a longer lifespan compared to other heating systems. Moreover, they require minimal maintenance, contributing to cost savings over time.

Let the Experts Install Your Boiler!

Boilers also provide versatility by accommodating different fuel sources, including gas, oil, and electricity. Their ability to generate hot water or steam for various applications, like space heating, domestic hot water, and industrial processes, adds to their versatility. Overall, the efficiency, reliability, and flexibility of boilers make them an excellent choice for efficient and effective heating solutions.

However, to ensure that you install your boiler safely and accurately, it is best to let professionals do the work. Patriot Boiler provides expert installation and other boiler services that guarantee your heating systems work effectively. Contact us today!

Recent Comments