Pressure vessels are integral to various industries, from manufacturing to energy production and our everyday lives. These vessels are designed to contain and withstand high-pressure fluids, gases, or even solids, making them a critical component of many industrial processes. In this in-depth exploration, we will unravel the engineering behind the pressure vessel, how they work, their various applications, and the importance of safety measures when dealing with high-pressure environments.

Pressure vessels are engineering marvels that play a crucial role in various industries, from manufacturing and energy production to aerospace and beyond. But what exactly is a pressure vessel, and how does it work?

Defining Pressure Vessels

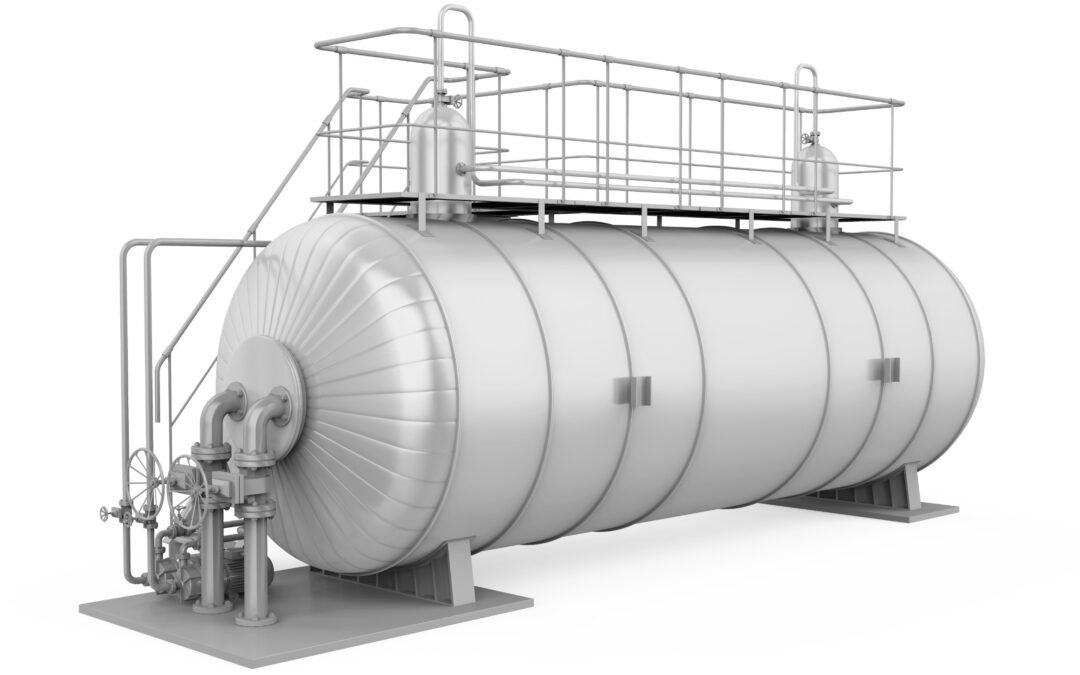

Pressure vessels are containers intended to hold gases or liquids at a pressure remarkably higher or lower than the surrounding ambient pressure. These vessels are engineered to withstand internal pressure, ensuring the contents remain safely contained. They also come in various shapes and sizes, from small cylinders to massive tanks, and their design and construction adhere to strict engineering standards and regulations. This comprehensive article will demystify pressure vessels, exploring their definition, functions, types, and vital role in maintaining our modern way of life.

Critical Elements of a Pressure Vessel

It’s essential to be familiar with its key components and characteristics to understand how a pressure vessel would work:

1. Vessel Body: This primary structure contains the fluid or gas under pressure. It is typically cylindrical, although other shapes are viable for specific applications.

2. Pressure Vessel: Pressure vessels are designed to handle varying degrees of internal pressure. The thickness of the vessel’s walls and the material used are determined by the pressure it will endure.

3. End Caps: These are the closures at the ends of the vessel, sealing it to maintain pressure. The shape of the end caps can vary, with some vessels having convex or dished ends to distribute stress more effectively.

4. Nozzles: Nozzles are openings in the vessel through which fluids or gases can enter or exit. They are typically equipped with flanges for connection to pipes or other equipment.

5. Supports: Large pressure vessels require robust supports to bear weight and prevent sagging or deformation. Supports are essential for safety and structural integrity.

6. Pressure Relief Devices: Pressure relief devices, such as relief valves and rupture discs, are designed to open and release excess pressure in the vessel to prevent over-pressurization.

Types of Pressure Vessels

Pressure vessels are classified into various types based on their purpose and design. Some common categories include:

1. Boilers: Boilers are pressure vessels that generate steam, typically for heating or power generation. They are found in industrial settings, power plants, and residential heating systems.

2. Storage Tanks: These vessels store various substances, such as liquids and gases. Common examples include oil storage tanks and compressed gas cylinders.

3. Reactors: Reactors are vessels designed for chemical reactions, often under high pressure and temperature. They are crucial in the chemical and petrochemical industries.

4. Heat Exchangers: Heat exchangers transfer heat between two or more fluids, often without allowing them to mix. They are used in heating, cooling, and various industrial processes.

5. Pressure Vessels for Nuclear Applications: These vessels are found in nuclear power plants and are essential for maintaining the nuclear reactor’s integrity.

How Does a Pressure Vessel Work

The primary function of a pressure vessel is to safely contain and control the pressure of the fluid or gas it houses – here’s how it should work:

1. Pressure Containment:

Pressure vessels are designed to maintain internal pressure at a level different from the external environment. The vessel’s robust construction and material strength ensure the pressure remains within safe limits.

2. Pressure Distribution:

The vessel distributes the internal pressure evenly across its walls, minimizing stress concentrations and preventing localized weakening.

3. Material Strength:

The vessel’s material strength is crucial. It must withstand internal pressure without deformation or rupture. The vessel’s geometry and thickness ensure the material can resist the applied pressure.

4. Temperature Control:

In some applications, pressure vessels are also designed to handle high temperatures. Heat transfer surfaces or insulation may be incorporated to manage temperature changes.

5. Safety Measures:

Safety devices like relief valves and rupture discs are incorporated into the vessel’s design. These devices are set to open at specific pressure thresholds, releasing excess pressure and preventing overpressurization.

6. Maintenance and Inspection:

Regular maintenance and inspection are vital to ensure that the vessel continues to operate safely. To prevent potential failures, it would be best to promptly address any signs of wear, corrosion, or damage.

The Engineering Behind Pressure Vessels

A pressure vessel is designed precisely and adheres to stringent engineering standards to ensure it operates safely and works effectively. Here’s a closer look at the critical engineering principles behind their construction and function:

1. Material Selection:

The choice of materials is critical in pressure vessel design. The material must be strong enough to withstand the desired pressure, temperature, and potential corrosive effects of the contents. Common materials comprise carbon steel, stainless steel, and various alloys.

2. Design Codes and Standards:

Industry-specific codes and standards, such as the ASME Boiler and Pressure Vessel Code in the United States, govern pressure vessel design. These codes outline design criteria, construction methods, inspection requirements, and testing procedures.

3. Stress Analysis:

The design process involves stress analysis to ensure the vessel can withstand internal pressure. Engineers calculate various stress factors, such as hoop (circumferential stress) and longitudinal stress, to determine the material thickness and structure’s geometry.

4. Thickness Calculation:

The vessel’s wall thickness is calculated to withstand the intended pressure without rupturing. Factors like the vessel’s diameter, material properties, and design pressure are considered in this calculation.

5. Welding and Joints:

Welding is a standard method of joining pressure vessel components. The quality of welds is critical to ensure the vessel’s integrity. Thus, non-destructive methods like radiography and ultrasonic testing inspect welds.

6. Pressure Testing:

Pressure vessels undergo rigorous testing before being put into service to ensure they can handle the intended pressure. Standard tests include the hydrostatic test, where the vessel is filled with water and pressurized, and the pneumatic test, which uses air or gas.

7. Safety Devices:

A pressure vessel has safety devices, such as relief valves, rupture discs, and pressure gauges, to prevent overpressure and ensure its safety and surroundings.

Pressure Vessel Work for Various Industries

Pressure vessels find applications across a broad spectrum of industries and sectors. Here are some typical applications:

1. Power Generation:

They are used in power plants to generate steam, which drives turbines to manufacture electricity.

2. Oil and Gas Industry:

They are employed in oil refineries and petrochemical plants for distillation and storage.

3. Chemical Industry:

Pressure vessels are crucial for chemical reactions, including polymerization, hydrogenation, and synthesis.

4. Food and Beverage Industry:

They also play a role in food processing, including sterilization, pasteurization, and cooking.

5. Aerospace:

Pressure vessels are used in spacecraft and aircraft for various applications, such as fuel storage and cabin pressurization.

6. Pharmaceutical Industry:

They are also adequate for sterilizing equipment and producing pharmaceuticals.

7. Water Treatment:

Pressure vessels are helpful in water treatment plants for processes like filtration and reverse osmosis.

8. Nuclear Industry:

They are vital components of nuclear power plants, housing reactors, and coolant systems.

9. HVAC Systems:

Pressure vessels are used in heating, ventilation, and air conditioning systems for pressure storage and temperature control.

10. Manufacturing:

Pressure vessels also find applications in various manufacturing processes, such as welding, extrusion, and molding.

Safety Considerations

Safety is paramount when dealing with pressure vessels due to the potential risks associated with high-pressure environments. Some essential safety considerations include:

1. Regular Inspection: Routine inspections are crucial to identify and address signs of wear, corrosion, or damage, which in turn helps prevent potential failures.

2. Proper Installation: Pressure vessels must follow correct installation by the manufacturer’s guidelines and industry standards.

3. Pressure Relief Devices: Equipping pressure vessels with appropriate pressure relief devices, such as relief valves and rupture discs, is essential to prevent over-pressurization.

4. Training and Certification: Personnel responsible for operating, inspecting, or maintaining pressure vessels should receive proper training and certification.

5. Emergency Response: Adequate emergency response plans and procedures should be in place in case of a pressure-related incident.

Risks Associated

Pressure vessels play a crucial role in various industries but also have inherent risks, especially when the design, operation, and maintenance are incorrect. These risks can have serious consequences, including personal injuries, environmental damage, and financial losses. So, understanding the potential risks associated with pressure vessels is essential for guaranteeing their safe and reliable operation. Here are some of the critical dangers with pressure vessels:

-

Rupture or Explosion

The potential for rupture or explosion is the most significant risk associated with pressure vessels. When a ship cannot withstand the pressure it contains, it can burst, releasing its contents with extreme force. Thus, it can cause severe injuries or fatalities and extensive damage to the surrounding area.

-

Leaks

Even without a catastrophic rupture, pressure vessels can develop leaks over time. Moreover, these leaks can release hazardous or flammable materials, posing risks to personnel and the environment.

-

Corrosion and Material Degradation

Corrosion and material degradation can weaken the vessel’s structural integrity over time. It may also reduce pressure resistance and increase the risk of failure. Thus, regular inspections and corrosion prevention measures are essential to mitigate this risk.

-

Overpressure

Operating a pressure vessel at pressures higher than its design limits can lead to overpressure, increasing the risk of rupture. It can occur due to equipment malfunctions, operator errors, or system failures.

-

Temperature Extremes

Pressure vessels that handle high-temperature fluids or gases are at risk of thermal stress and material degradation. So, they can become vulnerable to failure if not suitably designed and maintained.

-

External Forces

Pressure vessels may be exposed to external forces, such as seismic activity, which can stress the ship more. Proper anchoring and reinforcement are necessary to mitigate these risks.

-

Lack of Safety Devices

Pressure vessels should be provided with safety devices, such as relief valves and rupture discs, to protect against over-pressurization. The absence or malfunction of these safety devices can lead to catastrophic failures.

-

Environmental Impact

The failure of a pressure vessel can result in the release of hazardous materials into the environment, causing pollution and long-term ecological damage.

It’s important to note that these risks are not uniform across all pressure vessels. Besides, the specific risks associated with a pressure vessel depend on its design, materials, operating conditions, and maintenance practices. To mitigate these risks, industry standards and regulations have been established to guide pressure vessel design, fabrication, inspection, and operation. Regular inspections, maintenance, and personnel training are also essential to risk reduction. Also, implementing safety protocols and having emergency response plans in place can help minimize the impact of potential accidents involving pressure vessels.

Pressure Vessels are Essential in Various Industries

Pressure vessels are engineering marvels that play a pivotal role in various industries. Moreover, their ability to contain and control high-pressure fluids and gases is essential for power generation and chemical manufacturing. Understanding the principles behind their design, construction, and operation is critical for ensuring safety and efficiency in their use. Engineers and technicians involved in the design, fabrication, and maintenance of pressure vessels adhere to stringent standards to guarantee that these vessels work reliably while minimizing risks. Furthermore, in our increasingly industrialized world, the role of pressure vessels is ever more crucial, making them a subject of ongoing technological advancement and safety enhancement.

Pressure vessels are integral to a wide range of industries, and their proper design, construction, and operation are critical for maintaining safety and efficiency in high-pressure environments. Understanding the principles behind their workings is essential, as engineers and technicians involved in their design, fabrication, and maintenance adhere to stringent standards to ensure their reliability. These engineering marvels continue to evolve and enhance safety measures to meet the demands of our increasingly industrialized world, providing the safe containment and control of high-pressure fluids and gases that drive our modern way of life.

Recent Comments