Neglected routine maintenance on your boilers is one of the biggest contributors to why boiler systems fail. Performing routine maintenance on your boiler doesn’t have to be complex. To maintain an efficient operation, something you can do daily performs a boiler blowdown on your system. A boiler blowdown removes accumulated solids that settle in the mud drum and also removes dissolved solids. Addressing these impurities is critical to the routine maintenance of your boiler on a daily basis. It will help to ensure your boiler system is running at its maximum efficiency.

Types of Boiler Blowdowns

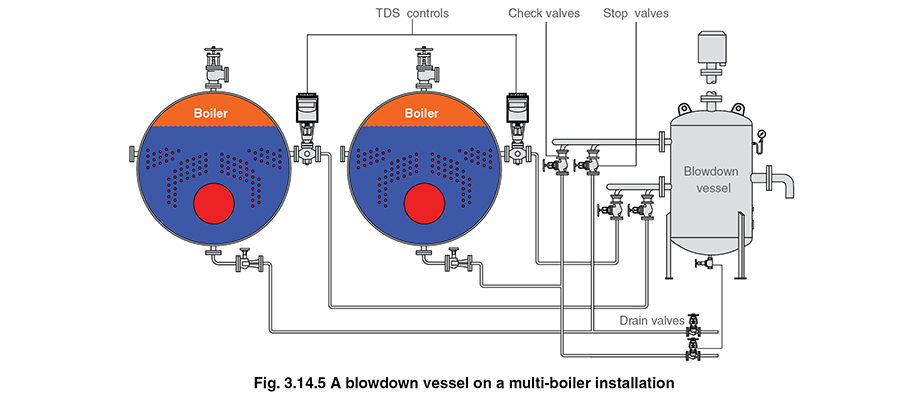

The two types of boiler blowdowns are surface and bottom blowdowns. A surface blowdown happens near the surface where the concentration of dissolved solids is at its highest. This blowdown removes the dissolved solids from the steam drum. If not removed from the boiler system, the dissolved solids would rapidly lead to scaling. Surface blowdowns should be done continuously with a metering valve or TDS sample automatic system.

A bottom blowdown happens at the bottom of the boiler, known as the mud drum. In this process, an operator manually removes the particles that settle in the mud drum. This is critical because the sludge must be removed before it builds up in the water that circulates past the heat transfer surfaces. The bottom blowdown should be performed once a shift. Both the surface and bottom blowdowns should be performed daily to reach maximum efficiency. Boiler blowdown is a simple way to extend the life of your boiler system.

Top-Rated Arizona Boiler Company

To learn more about how a boiler blowdown can benefit you, call Patriot Boiler at (480) 797-9349 to speak with our highly trained boiler experts. Patriot Boiler can take care of all your boiler service needs! Patriot Boiler will be glad to install these and give instructions for proper operation.

Recent Comments